Vantiva Precision BioDevices

Bringing Big Ideas to Life.

Your partner in Microfluidics Manufacturing and Precision Injection Molding

Research and development for microfluidic devices and injection molded products takes time and testing—constant iterations until you get it right. And when you do, how do you get it to market? It’s time that your prototype stopped being a prototype.

Design for Manufacturability – From 1 to 1 million

ISO 13485

Certified Innovation Center

Scalable manufacturing from small batches for testing to global distribution.

Expert Engineering and

Design Support

A Global Partner in the Injection Mold Tooling, Design and Development Process

When your designs require the utmost in fabrication quality and tight tolerances, you don’t have to go it alone. From microfluidic devices to injection molded medical devices and equipment, we get your designs to market with precision and speed at scale.

Making precision molding smarter, faster, and more accurate

Vantiva Precision BioDevices brings big ideas to life with a comprehensive suite of precision molding and microfluidic design and development capabilities.

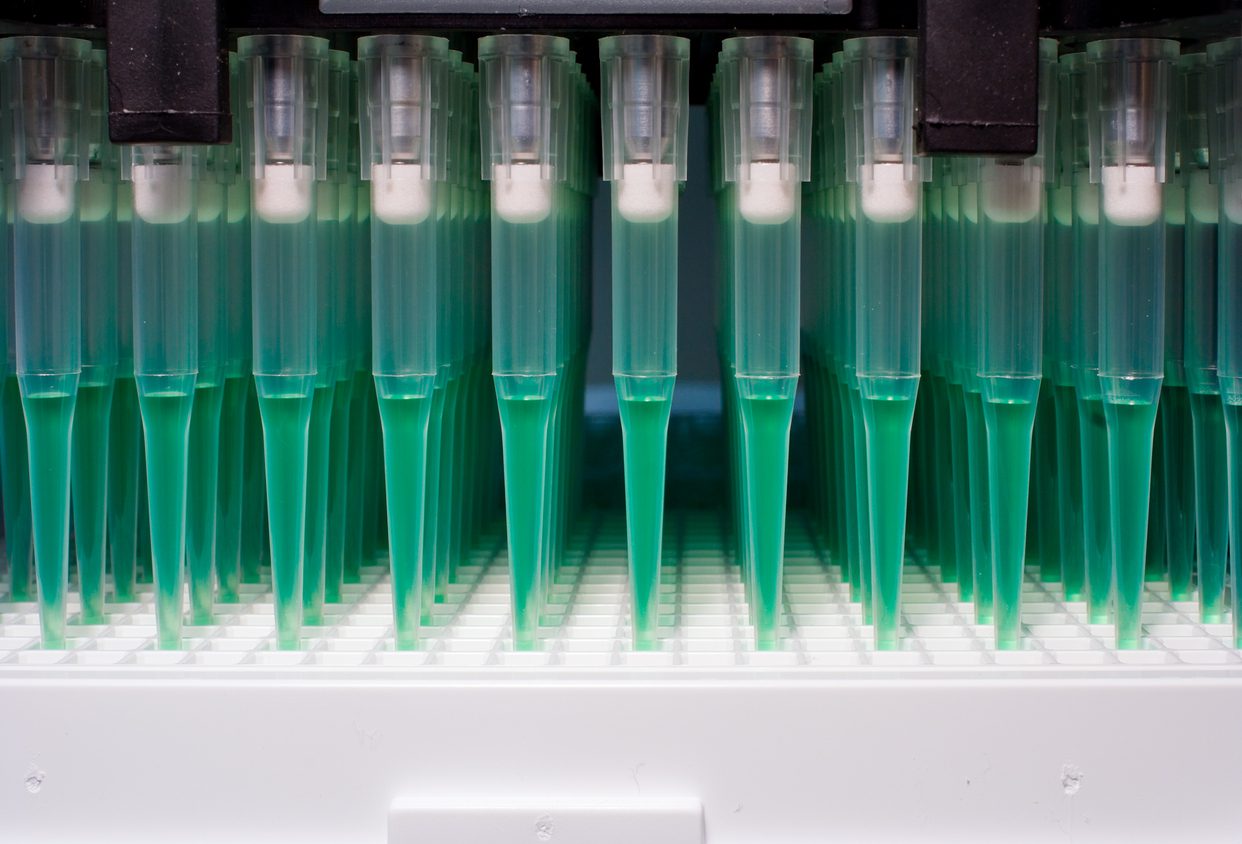

From ultra-precision micro-machining and injection molding to advanced assembly and inspection technologies, PBD utilizes a full range of available technologies to offer the highest quality, fastest microfluidics manufacturing and prototyping cycle.

- Advanced mastering, mold tooling, and manufacturing

- High resolution inspection technologies

- Laser welding, thermal fusion bonding, PSA lamination, solvent bonding, and ultrasonic welding assembly techniques

- ISO7 cleanroom processing, assembly and packaging

- Reagent integration and specialty coatings

- Microfluidic testing lab

- Full-service, in-house logistics and distribution

- Laser cut film converting

Bringing medical innovation to life with precision microfluidic technology for:

Drug

Discovery

Clinical

Diagnostics

Environmental

Monitoring

Point-of-Care

Testing

Life

Sciences

Veterinary

Science

Agricultural

Testing

Vantiva Precision BioDevices is an ISO 13485 certified Contract Manufacturer

providing custom development and manufacturing of polymeric microfluidic devices and precision injection mold tooling and production.

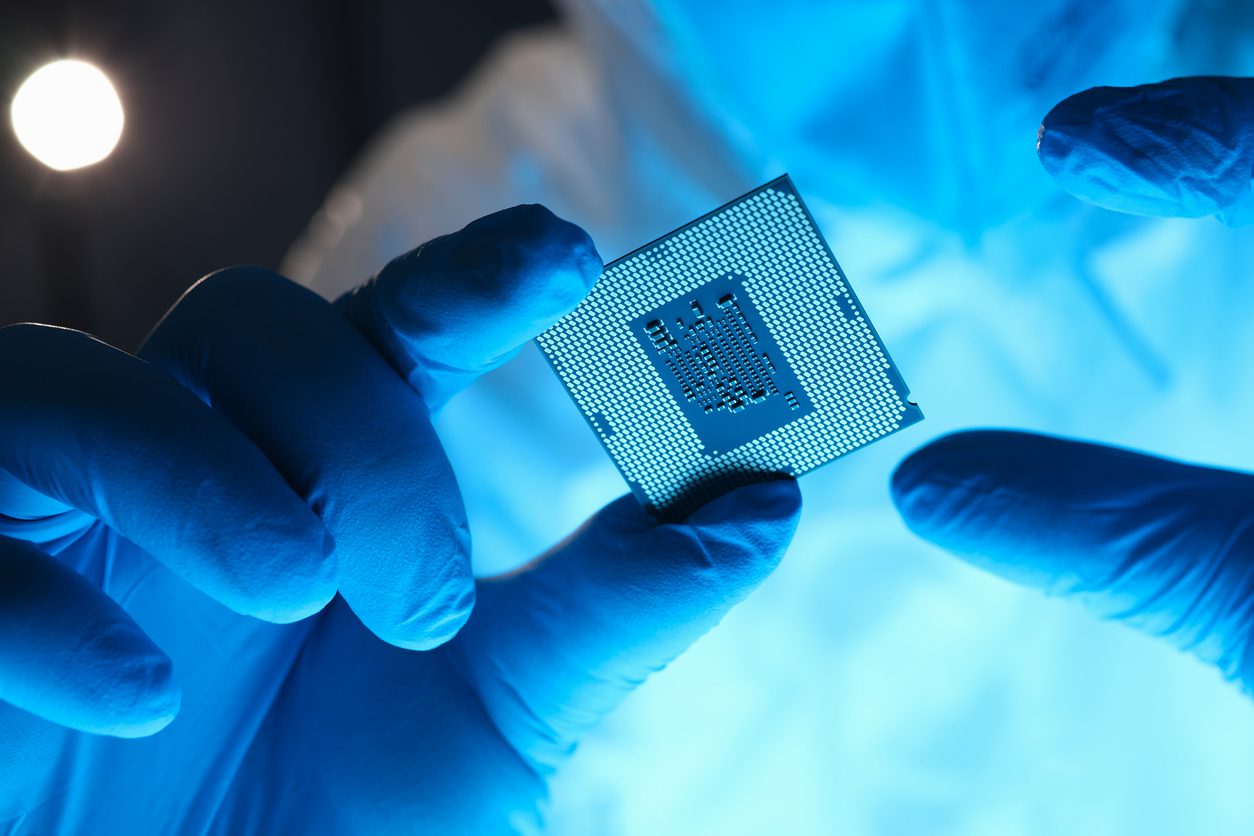

Vantiva Precision BioDevices’ Injection Molding Capabilities

With a full suite of cutting-edge mold tooling, assembly, and ultra-precise CNC machining centers, the Vantiva Innovation Center provides cost-effective local production facilities to biotech, medical, and aerospace hubs across the West Coast of the United States.

Precise Tooling and Custom Mold Bases Up to 570mm

State-of-the-Art Clean Rooms and Robotic Cells

Extensive Range in Materials and Assembly Techniques

From Rapid Prototyping to Production

We get you from design to market with speed and precision.

1

It all starts with a design

Whether you’re already on your way, or you’re looking for an engineering team to bring your idea to life, we’ve got you covered.

2

We prototype it

Utilizing our in-house precision mold tooling, CNC machining, and assembly equipment, our team will rapidly create a proof-of-concept for you to test, and refine. We’ll even make recommendations for cost-saving strategies.

3

Stamp of approval

Last, we’ll verify the design and move to production, be it a small batch for testing, or large quantities for global distribution.

LATEST NEWS

Exploring the Power of Microfluidic Chips for Single-Cell Sequencing and Analysis

Single cell isolation has become a must-have capability for biological research institutions the world over. In cancer research, immunology, neuroscience, microbiology, stem cell rese [...]

Selecting the Right Microfluidic Chip Fabrication Materials for Your Research

When designing new microfluidic chips for medical and scientific research applications, there is no shortage of factors to keep in mind for your device, from the initial back-of-the-n [...]

How Microfluidics Are Advancing Biomedical Research and Precision Medicine

The global biotech industry is a fast-moving, ever-growing environment—expected to reach over $3.6 trillion by 2032—as major players in the industry continue to search for solutions t [...]

CASE STUDIES

Optical Imaging Flow Cell – Clear-to-Clear Laser Welding

The Requirement: A hermetically sealed flow cell with clear cover and channel layers with uniform channel height and no adhesive contamination.

Solution: Vantiva’s unique contour laser welding technology seals clear-to-clear materials, no darker energy absorbing layer is needed resulting in a clear optical path.

Precision High Pressure Droplet Generator – Solvent Bonding

The Requirement: A complex, optically clear droplet generator and pillar array design is required for precision drop size, distribution and segregation operating under high pressure.

Solution: Vantiva’s solvent bonding enabled the assembly of clear-to-clear materials avoiding cover films with adhesives that could overflow and impact droplet formation, biocompatibility and different surface energies.

Nanoarrays

The Requirement: A cost effective and reproducible alternative to silicone as a substrate for a precision nano-pore microarray used for genomic analysis.

Solution: Vantiva provided reproducible injection molded microarrays with uniform spaced pores as small as 20um in diameter performing well in the NGS application and at a reduced cost.