Bringing big ideas to life is hard.

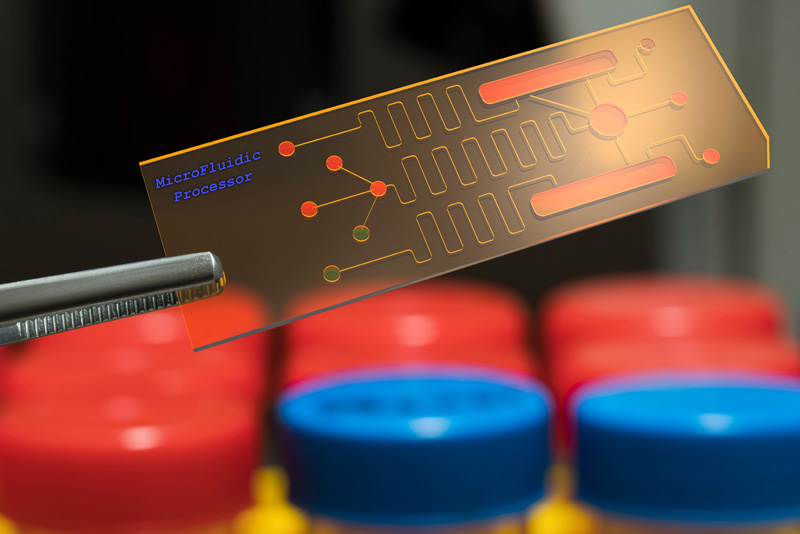

Microfluidic device R&D takes time and testing – constant iterations until you get it right. And when you finally do, your next challenge is getting it to market.

Transferring a microfluidic chip design from the bench to cost-efficient manufacturing and distribution processes can mean risking materials, equipment and logistics costs, labor, time, and more. For a company of your size, shouldering risks like those might prevent your dream product from ever getting off the ground.

That’s where a global strategic partner comes in.

We’re here to take the risk out of bringing your microfluidic devices to life.

Contract manufacturing and development for risk mitigation helps you optimize your strategic, financial, and technical positions. As global Strategic Partners in microfluidics assembly, design, and more, Vantiva Precision BioDevices applies peerless development and logistics expertise to make your medical innovations a reality at any scale – from one to one million.

Rapid Prototyping

We can build it faster, better, smarter – producing lab-on-a-chip prototypes at industry-leading turn times.

Competitive Pricing at Scale

Our streamlined development process keeps costs competitive at any scale, from small batches for testing to

global distribution.

Global Logistics Capabilities

We take you from start to finish with comprehensive development services and global manufacturing/supply-chain capabilities.

We Are Your Strategic Microfluidic Chip Manufacturers

With over 30 years of precision injection-molding expertise and global logistics capabilities, we offer end-to-end solutions to your design, production, and distribution challenges. Our team helps you find the best, most cost-effective solutions to produce your microfluidic product at any scale through a proven product realization stage-gate process.

Our extensive microfluidics assembly and design capabilities include:

Mastering and Mold Tooling

From lithography to DRIE to ultra-precision micro-machining, we develop state-of-the-art production injection molding toolings and processes to bring your microfluidic product to life and transfer from prototype to high-volume manufacturing.

- Lithography

- DRIE

- Ultra Precision Micro-Machining

- ISO 14644 Class 7 Clean Rooms for Processing, Assembly, and Packaging

Manufacturing

We select the injection molded polymers and extruded films that work best for your product functionality. Our material specialties include, but are not limited to, widely-used polymers such as:

- Cyclic Olefin Polymer (COP)

- Cyclic Olefin Copolymer (COC)

- Polypropylene (PP)

- Polycarbonate (PC)

- Polystyrene (PS)

- Polymethyl Methacrylate (PMMA)

High Resolution Inspection

At microfluidic scales, the smallest details make the biggest differences. Our high-resolution inspection capabilities include advanced metrology systems to assess and monitor critical dimensional metrics for your lab-on-a-chip products and ensure the highest production quality.

- Laser Confocal and Optical Microscopes

- Atomic Force Microscopy

Assembly Techniques

Comprehensive expertise in microfluidic chip production requires a thorough understanding of the wide range of of available assembly, bonding, and welding techniques, including:

- Laser Welding – incl. clear-to-clear

- Thermal Fusion Bonding

- PSA Lamination

- Solvent Bonding

- Ultrasonic Welding

- UV Resin Bonding

Our additional capabilities include reagent integration and specialty coatings, comprehensive microfluidic testing laboratory services, and laser-cut film converting. Our logistics and distribution capabilities are in-house and full-service to minimize your own resource and capital investment and leave you with more to focus on your own core offerings.

Our Microfluidic Devices Portfolio

Our vast experience in designing, assembling, and distributing microfluidic devices covers a wide range of applications across a broad industry portfolio. Here’s just a sample of the microfluidic chip products we’ve helped bring to life for clients in life sciences and beyond:

Droplet Generators

Precision Flow Cells

Microwell and Micropillar Arrays

AST Cartridges

ELISA Chips

PCR Cartridges

Organ-on-a-Chip

Cell Isolation and Cell Sorting Chips

Optical Lens and Feature Integration

Ready to bring your microfluidic devices to life?

How We Design Microfluidic Chips for Manufacturability

The perfect microfluidic chip design plays a delicate balancing act between optimizing material selection, mold design, and process capabilities to ensure that the microfluidics assembly process is both physically feasible at your scale and cost-effective.

Our engineering team works with you through the injection molding process to:

- Enhance decision-making to provide the most precise and reproducible product outcome

- Optimize your design for materials, complexity, and processing steps required for functionality

- Leverage existing solutions and identify/develop manufacturing controls

- Reduce risk through prototyping, processing viability, and other means

Our Strategic Partnership Capabilities

Working with us as a strategic partner for microfluidics assembly, design, and distribution optimizes your financial, strategic, and technical positions.

Microfluidic Chip Manufacturing Partnering enables you to:

- Establish new manufacturing lines while freeing up capital for core business investments

- Assure supply continuity

- Establish a manufacturing blueprint for growing companies

Development Partnering provides you with:

- A cross-functional understanding of your objective

- An efficient and targeted approach to achieving manufacturable microfluidic devices

- Secure ownership of your Intellectual Property

Four Ways to Reduce Risk in Microfluidic Chip Manufacturing

Prototyping

We start with a design and simulation to rapidly create proof-of-principle samples for iterative testing. Vantiva Precision BioDevices experts carefully consider processing and cost reduction strategies before moving to design verification and validation for production manufacturing.

Process

The Vantiva Precision BioDevices proven stage-gate production process leads you smoothly from initial design to commercial product. We cover all the bases for risk identification and mitigation processes required for clinical testing, filings, and regulatory approval in your industry.

Through Technology

At Vantiva Precision BioDevices, we are constant innovators, building on 100 years of technological expertise to develop and and integrate new function and processing technology and stay on the cutting edge of microfluidic chip assembly and scale production.

Through Security

Descended from a tradition of over 100 years of exceptional technological and logistics expertise, Vantiva Precision BioDevices has a long corporate history of protecting and being trusted with sensitive Intellectual Property and other confidential information.