Your Partner in Microfluidics Manufacturing

With our precision, accuracy, and global logistics expertise, you can bring your projects full circle, manufactured to the highest standards with no budget or supply chain headaches.

Researching and developing microfluidic devices takes time—iteration after iteration, test after test, until you get it right. As for getting your device to market, that’s an ordeal of its own. Turning your prototype lab-on-chip microfluidic technology into a world-changing medical device takes engineering and logistics expertise.

Vantiva Precision BioDevices connects you to the expertise you need to make microfluidics manufacturing fast and precise.

Vantiva is a global partner in the world of microfluidic chip manufacturers.

From design iteration to rapid prototyping to global production logistics, Vantiva brings microfluidics, nano fabrication, bioengineering, optical engineering, biotech, and material science expertise to realize the cutting-edge in microfluidic lab-on-chip devices.

Vantiva Precision BioDevices is an ISO 13485 certified Contract Manufacturer with over 35 years injection-molding experience, a proven track record of developing and manufacturing IVD medical devices, and extensive global production and logistics expertise.

Create your own lab-on-chip devices

Microfluidics, the manipulation of extremely small amounts of fluids, enables the operation of incredibly small microelectromechanical systems that perform single or multiple laboratory processes, often called lab-on-chip devices. Lab-on-chip devices enable efficient, portable, and above all, high throughput health screening and testing across the fields of health and life science.

Microfluidic chips demand rigorous and cutting-edge manufacturing processes, technologies, and techniques. At Vantiva, we work with you to bring your ideas for new and innovative lab-on-chip devices to life, offering hands-on rapid prototyping, competitive pricing and cost leadership, and global logistics support to speed up and streamline the long, often arduous process of bringing your new microfluidic product to market.

Bring your biggest ideas to life across the spectrum of the medical and life sciences field:

Drug

Discovery

Clinical

Diagnostics

Point-of-Care

Testing

Life

Sciences

Agricultural

Testing

Veterinary

Science

Microfluidics Manufacturing Case Studies

Microfluidic chips depend on extremely precise nano-engineering, utilizing cutting-edge technology, to isolate and perform analytical tests on individual cells from biological samples, with a wide range of applications from cancer screening to point-of-care testing and beyond.

When other microfluidic chip manufacturers and microfluidics companies struggle to overcome the technical and logistical challenges in bringing their ideas to life, Vantiva is here to support them with ingenious, cutting-edge solutions.

Optical Imaging Flow Cell – Clear-to-Clear Laser Welding

The Requirement: A hermetically sealed flow cell with clear cover and channel layers with uniform channel height and no adhesive contamination.

Solution: Vantiva’s unique contour laser welding technology seals clear-to-clear materials, no darker energy absorbing layer is needed resulting in a clear optical path.

Precision High Pressure Droplet Generator – Solvent Bonding

The Requirement: A complex, optically clear droplet generator and pillar array design is required for precision drop size, distribution and segregation operating under high pressure.

Solution: Vantiva’s solvent bonding enabled the assembly of clear-to-clear materials avoiding cover films with adhesives that could overflow and impact droplet formation, biocompatibility and different surface energies.

Nanoarrays

The Requirement: A cost effective and reproducible alternative to silicone as a substrate for a precision nano-pore microarray used for genomic analysis.

Solution: Vantiva provided reproducible injection molded microarrays with uniform spaced pores as small as 20um in diameter performing well in the NGS application and at a reduced cost.

Our Microfluidics Manufacturing Process – From Design to Production

We get you from design to market with speed and precision.

1

Design It

Whether you’re already on your way, or you’re looking for an engineering team to bring your idea to life, we’ve got you covered.

2

Prototype It

Vantiva brings unmatched speed and precision to the rapid prototyping process to produce a proof-of-concept you can test and refine. We also provide recommendations to perfect your product.

3

Produce It

Vantiva brings a century of engineering and logistics expertise into the world of microfluidics manufacturing to bring your lab-on-chip device to market at any scale–from one to one million.

Created by VPB engineers, our free Design Guide helps you get a head start on making your lab-on-chip design as efficient and cost-effective as it can be.

Our Microfluidic Chip Design Guide reveals everything you need to streamline the design of your next big lab-on-chip product, including design recommendations for efficient manufacturing workflows, injection molding form factors and channel specifications, and more!

Making precision molding smarter, faster, and more accurate

Vantiva Precision BioDevices brings big ideas to life with a comprehensive suite of precision molding and microfluidic design and development capabilities.

From ultra-precision micro-machining and injection molding to advanced assembly and inspection technologies, PBD utilizes a full range of available technologies to offer the highest quality, fastest microfluidics manufacturing and prototyping cycle.

- Advanced mastering, mold tooling, and manufacturing

- High resolution inspection technologies

- Laser welding, thermal fusion bonding, PSA lamination, solvent bonding, and ultrasonic welding assembly techniques

- ISO7 cleanroom processing, assembly and packaging

- Reagent integration and specialty coatings

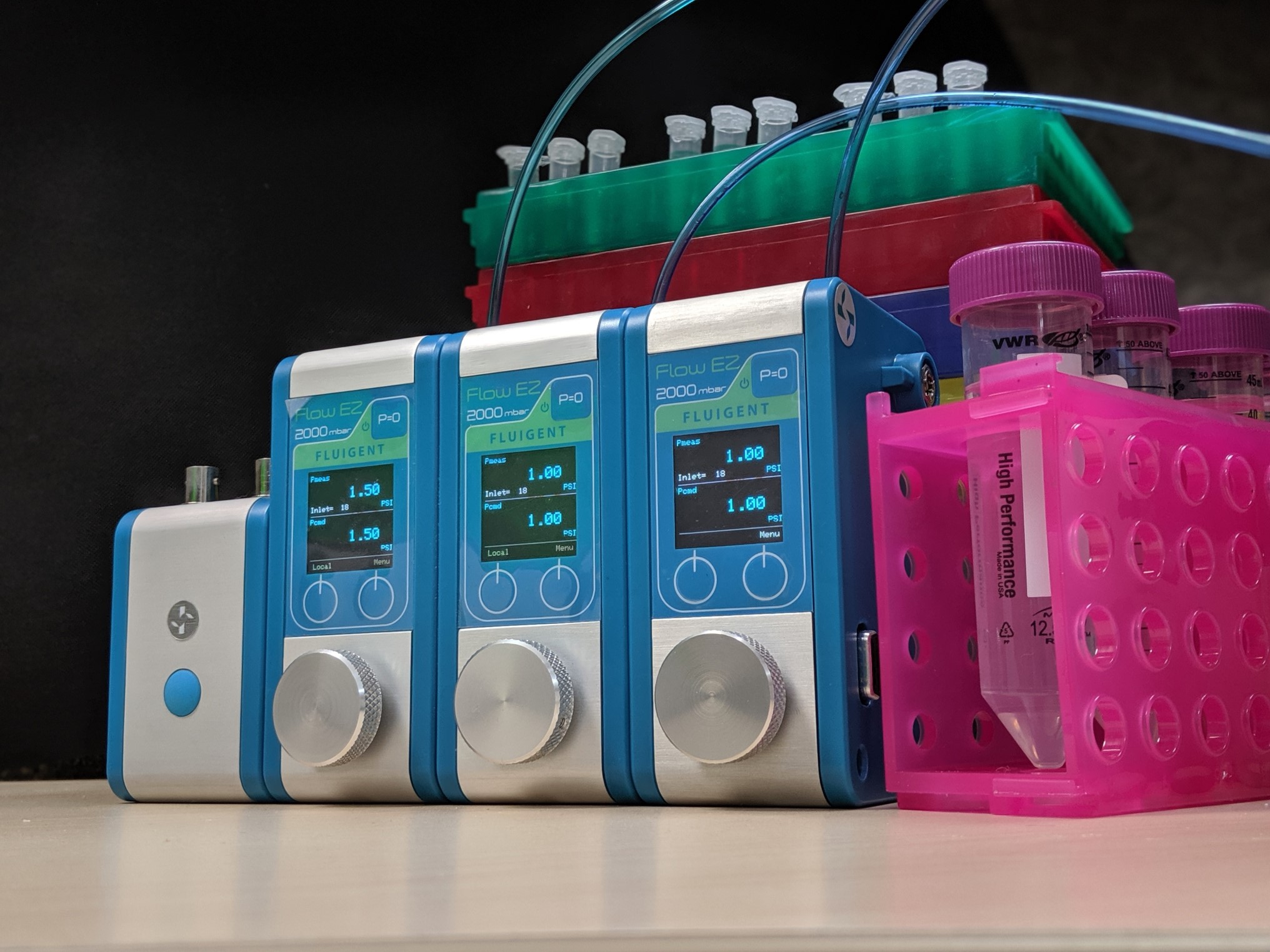

- Microfluidic testing lab

- Full-service, in-house logistics and distribution

- Laser cut film converting

Microfluidic Design and Rapid Prototyping

Vantiva Precision BioDevices is more than just a microfluidic manufacturer. We don’t just build—we connect you to the engineering and logistics expertise you need to design, ideate, iterate, prototype, produce, and distribute at any scale—from one to one million units—all while keeping your costs down.

Throughout our microfluidic manufacturing process, we provide expert advice every step of the way to take your dream product further than you could have imagined, speeding along your design process, bringing more efficiency into your manufacturing workflows, and making your prototypes and final products more cost-effective.

The Vantiva Advantage

Vantiva combines cutting-edge and forward-thinking engineering and knowledge leadership in lab-on-chip manufacturing with price leadership and the ability to scale up high volume manufacturing, shipping, and logistics to provide the very best results among microfluidic chip manufacturers while keeping costs down.