Protective housings for pumps and diagnostic equipment, surgical instruments such as forceps and clamps, the plunger rods and needle hubs for syringes, prosthetic and orthopedic components, pharmaceutical packaging, implantable medical devices, and, of course, lab-on-a-chip diagnostic devices—these are just a few of the products medical professionals rely on every day to deliver effective treatment and improve the quality of patients’ lives.

These are also just a few of the medical products whose manufacturing has been transformed by advances in precision injection molding. As injection molding methods and technologies evolve, manufacturers gain the ability to produce more and more intricate parts at smaller and smaller scales, further expanding the capabilities of medical professionals all around the world.

Let’s take a look at the history of medical injection molding and see how we got here and where we’re going:

The Evolution of Medical Precision Molding

Precision injection molding has become an essential method for producing medical devices and equipment. Modern molding technology allows for the high-throughput, cost-effective mass production of medical equipment with reliable and consistent results. But like all technologies, it didn’t start out that way.

Injection Molding – The Early Years

Injection molding was invented in the 1930s by John Wesley Hyatt, an inventor with over 200 patents to his credit who is now best known for his innovations in celluloid. Initially, injection molding was used to fabricate simple objects. However, in the 1940s and 1950s following World War II, rapid growth and development of the plastics industry brought injection molding into the forefront as a useful method for rapidly mass-producing products from this revolutionary new material.

Medical Devices – The Plastic and Polymer Revolution

It wasn’t until the later 1950s and the 1960s that injection molding began to really catch on for medical device manufacturing. Plastics proved to be far superior to glass and metal for medical equipment such as syringes, tubing, and catheters, significantly reducing manufacturing costs while also improving the safety of these products.

Throughout the latter half of the 20th Century and the early 21st century, as new plastic materials were synthesized and investigated, medical manufacturers discovered new ways to ensure that injection-molded medical devices were easier to sterilize and less likely to cause adverse patient reactions.

Today, advanced biocompatible and bioresorbable polymers make surgical instruments, drug delivery systems, implantable devices, and diagnostic components more effective and efficient than ever before.

Medical Injection Molding Meets the Digital Age

Medical injection molding truly became precise with the advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. Initially developed in the 1960s, CAD and CAM tools became ubiquitous in every manufacturing industry by the 1990s, enabling manufacturers to make their designs even more complex and intricate to suit ever more specific medical needs.

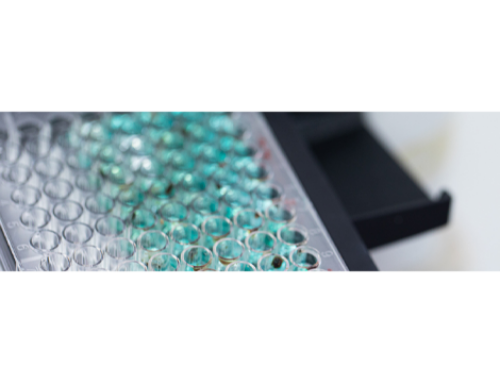

In the 2000s through to the present day, modern medical precision molding as we know it took shape. Advances in micro-injection molding have pushed the envelope again and again to produce smaller and more precise medical components, from microfluidic devices that can rapidly analyze extremely small material samples to intricate micro-electromechanical systems and micro-optics for implants and diagnostic tools.

Precision Medical Molding Today

Additive manufacturing has also recently provided an incredible boon to medical device manufacturers—the ability to rapidly iterate on prototypes and develop customized medical devices and equipment in order to realize innovative new ideas and get them to the market as usable products, faster.

Injection molding has come a long way from Hyatt’s original invention. Little by little, new developments in plastics, production processes and tools, and scientific knowledge continue to push medical injection molding to new heights.

Today, precision molding provides a wealth of efficiency and cost-effectiveness improvements to medical device manufacturing processes, such as:

- Control over extremely tight tolerances that ensures products meet the exact specifications demanded by market needs and regulatory bodies with reduced need for post-processing

- Reduced material waste due to the incredible efficiency of precision molding techniques, lowering the costs of expensive or specialized materials

- Highly automated machinery that minimizes the need for manual labor and ensures high production rates and consistent product quality

- Shorter cycle times due to the ability to rapidly complete injection and cooling processes

- Scalability to accommodate changes in manufacturing volumes necessitated by shifts in product demand, reducing the risks of overproduction or underproduction

How Precision Molding Has Changed the Medical Device Market

Today, the ability for medical device manufacturers to access the expertise of contract manufacturers in the injection molding space have unlocked a plethora of new possibilities in the medical device market.

- Engineers and designers have the flexibility to innovate to an unprecedented degree, creating smaller, more precise, more efficient devices.

- Medical device manufacturers have led the way in providing healthcare professionals with tools to make medical procedures minimally invasive, increasing patient comfort.

- Manufacturers can make use of a wide range of biocompatible materials that reduce the risk of adverse reactions or complications.

- It’s easier now than ever to manufacture customized and even patient-specific medical devices, such as implants and prosthetics.

- Time-to-market for medical devices has become significantly shorter, thanks to advances in rapid prototyping.

- Scaling up from low-volume to high-volume production to meet demand or expand into new regions is easier than ever.

Unleash Medical Device Injection Molding

With the help of a strategic design and manufacturing partner, the sky’s the limit for medical plastic injection molding. Utilizing state-of-the-art injection molding, micro-machining, and micro-assembly technologies and techniques, Vantiva Precision BioDevices has led the way in bringing our clients’ precision medical devices to life.

In a world filled with trailblazers, it takes a strategic partner to bring your designs to life. From microfluidic devices to custom medical device injection molding, we’re here to help you bring your design to market with unparalleled precision, accuracy, and global expertise. Contact our engineers today to get started.