Every industry grapples with the growing problem of waste, and nowhere is this more keenly felt than in the healthcare industry. Healthcare waste (HCW) comes in many forms—including sharp single-use medical instruments, contaminated and infectious materials, medications and chemicals, and non-hazardous waste. According to the National Institute of Health, the United States alone generates 8.4 to 10.7 kilograms of HCW per bed per day. At the peak of the COVID-19 pandemic, in Wuhan, China alone at least 240 tons of HCW were produced per day.

Healthcare waste is an inevitable part of healthcare. Bandages, gauze, and dressings cannot be used for one patient and then re-used for another. Single-use medical tools, protective equipment, and other types of HCW, hazardous and non-hazardous alike, have rigorous regulatory structures for handling their disposal and management to prevent adverse effects on human and environmental health. However, especially in developing nations that lack robust healthcare infrastructure, the mechanisms to ensure the proper disposal of hazardous and non-hazardous HCW alike often prove insufficient.

Finding ways to minimize waste with these constraints is a pressing and urgent issue in the healthcare industry. Today, methods such as the circular processing of surgical waste into high-quality material are being investigated as potential ways to reduce HCW.

There is no single “silver bullet” solution to the problem of HCW, however. Rather than a miracle panacea for reducing waste in the healthcare industry, there are a host of solutions all working in concert throughout the lifetime of the medical products we rely on every day, from fabrication to disposal.

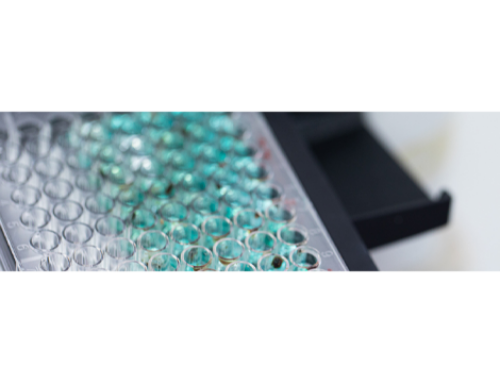

And starting with fabrication, medical injection molding plays a significant role in creating a more sustainable healthcare industry. From reducing energy consumption and material waste to utilizing sustainable and biodegradable plastics, medical device injection molding lays a foundation for greater sustainability in the healthcare industry.

Exploring the Environmental Impact of Injection Molding

One of the advantages of medical injection molding, and indeed injection molding in general, is that as a method of industrial mass production, it is an inherently low-waste process that produces less leftover material than other production methods.

Injection molding and sustainability have not always gone hand-in-hand, though. Plastic is itself derived from fossil fuels, and for most of its history, industrial injection molding relied on hydraulic machines that ran on oil, though these are now being phased out by more energy-efficient electric molding machines.

As technology evolves, injection molding does more and more to offset its own negative environmental impacts and highlight the positives. Injection molding machines are becoming more energy-efficient, and increases in capacity are improving manufacturing throughput and efficiency as well, enabling injection molding facilities to do more with less. Advances in biodegradable and recycled plastic materials are also playing a critical role in reducing the medical industry’s dependency on fossil fuels while also producing less waste.

Medical Injection Molding and Energy Consumption

Injection molding, when it was first developed in the 1930s, was not initially concerned with reducing waste or being sustainable, though it did have its own advantages over other fabrication methods for plastic products. Through the 1950s and 60s, when injection molding caught on as an indispensable tool for the production of medical devices, up to the present day, injection molds relied on hydraulics and required significant energy consumption due to their need to heat plastics up to extremely high temperatures.

Today, though, electric machines are taking over older hydraulic machines, providing new ways for manufacturers to improve injection molding sustainability and energy efficiency.

Some of the ways electric machines reduce injection molding energy consumption compared to hydraulic equipment include:

- The use of electric servo motors for the injection, clamping, and ejector processes uses less energy during the molding cycle. Hydraulic systems must continuously consume energy to maintain pressure, but electric servo motors only consume energy when actively functioning.

- Regenerative braking, a feature on some electric injection molding machines, can convert kinetic energy from the deceleration phase back into electrical energy to power other machine functions.

- The ability to fine-tune the cooling process allows more efficient use of cooling resources.

- The lack of need for hydraulic oil eliminates the need for energy-intensive oil heating.

- Electric injection molding machines have lower standby energy consumption compared to hydraulic machines, which often need to maintain pressure in the system even when not actively molding.

The adoption of electric injection molding machines is a fundamental part of the industry’s sustainability goals as it strives to reduce its carbon footprint and reduce injection molding energy consumption.

Reducing Injection Molding Waste

Since electric injection molding machines provide more precise control than traditional hydraulic machines, there is less chance of overfilling molds, reducing the amount of energy needed to melt and process plastics. But this precision accuracy doesn’t just reduce injection molding energy consumption—it also reduces material waste.

Electric injection molding machines make it easier to ensure accurate, consistent shot sizes that reduce the likelihood of overfilling molds. Precise control optimizes material usage with consistent and repeatable processes. Because they have more finely tuned control over cooling as well, electric injection molds prevent warpage or defects—minimizing the need for reworking or scrapping produced parts.

Modern electric injection molding equipment also often incorporates closed-loop control systems that ensure the entire molding process remains within specified tolerances and optimize the molding process to achieve the desired part quality with minimal injection molding waste.

Using Sustainable Plastic for Medical Device Injection Molding

Utilizing biodegradable plastic for injection molding presents more opportunities to make medical injection molding more sustainable and reduce HCW.

Using sustainable plastic materials, such as recycled or biodegradable plastics, makes medical injection molding more environmentally friendly and reduces downstream healthcare waste in myriad ways.

Recycled plastics reduce the demand for virgin plastic resin, conserving natural resources and decreasing the environmental impact associated with extracting and processing raw materials. They also reduce plastic waste by repurposing post-consumer or post-industrial plastics into medical devices and components, which can be more easily recycled after a single-use medical device made from recycled plastic is disposed of.

Biodegradable plastic injection molding relies on renewable, often plant-based resources that reduce reliance on finite fossil fuel resources and contribute to a more sustainable production cycle. They break down into natural components over time, reducing the persistence of plastic waste in the environment. When carefully and thoughtfully disposed of according to healthcare industry processes, injection molded medical devices made from biodegradable materials can return their organic matter to the environment without negatively impacting human or environmental health.

How Precision Medical Injection Molding Minimizes HCW

As precision injection molding becomes more and more energy-efficient and material-efficient, its contributions to the healthcare industry’s commitment to reducing HCW become more pronounced. Today, medical device injection molding already offers many advantages for producing medical materials while minimizing waste, such as:

- Producing complex and detailed parts with intricate designs and precise dimensions with minimal material waste

- Ensuring tight tolerances and consistent quality, reducing the likelihood of parts needing to be disposed of due to manufacturing defects

- Optimizing and customizing designs for specific medical applications, eliminating unnecessary features and materials to minimize the amount of excess materials left behind

- Contributing to the optimization of single-use medical devices to make them more efficient, cost-effective, and environmentally friendly

- Allowing medical device designers to take advantage of sustainable plastics to produce recyclable or biodegradable medical products that reduce the environmental impact of HCW

- Supporting lean manufacturing practices that minimize wasted resources

Collectively, these factors all play a part in making precision medical injection molding a significant piece of the puzzle for combating the worldwide problem of medical waste.

To learn more about how a strategic partner in medical device injection molding can help you design, produce, and market the sustainable medical products you’ve been dreaming of and do your part to reduce medical waste, connect with our engineers today.