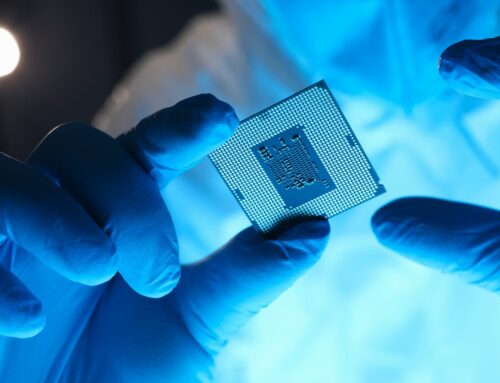

Designing and prototyping a microfluidic chip for lab-on-a-chip (LOC) devices used in research, assay, point-of-care testing, or drug discovery is a challenge in its own right, but sometimes it can be one of the less challenging parts of the production process compared to commercializing it.

Microfluidic product development isn’t easy in general, demanding powerful machining and molding tools and techniques, cross-disciplinary expertise, and, of course, patience—but what makes developing commercial microfluidic devices in particular so challenging? In this article, we’ll explore five major challenges associated with successfully getting your microfluidic systems on the market.

Why Getting Commercial Microfluidic Devices Out There is Hard

Commercial microfluidics is a large, fast-growing, and competitive market—but commercializing new products runs into a host of challenges that designers need to be able to address for their microfluidic systems and products to find their niche and succeed.

To turn a profit, assay tools, point-of-care testing tools, and other applications of LOC devices all need to find the right balance between being cost-effective to produce at the right scale and being genuinely innovative, reliable in the field, user-friendly, and affordable to their target demographic—no easy task!

Designing a microfluidic product in the first place means building a team with vast interdisciplinary expertise to address the unique needs and challenges of your market niche, gaining access to intricate and complex fabrication tools and processes, selecting compatible materials and appropriate bonding techniques to ensure reliability and prevent leakage or contamination, and effectively integrating pumps, valves, sensors, and other microsystems while maintaining performance and meeting high quality standards.

On top of that, some of the challenges you face in commercializing your microfluidic chip designs, depending on your specific application, market niche, and technologies involved may include:

1. Scaling Up for Mass Production

Prototype development is its own hurdle to overcome, but after that comes transitioning to mass production—which is the real challenge. At any scale, from small to mid to large-scale production volumes, scaling up while keeping your microfluidic chip cost-effective involves a great deal of process optimization for efficiency, cost-effectiveness, and quality—all the while building a larger workforce to handle production and taking into account the environmental footprint of production operations.

The larger you scale up production, the harder it becomes to maintain precision in your manufacturing processes and ensure consistent product quality. Throughput limitations or tooling costs associated with fabrication techniques such as photolithography and soft lithography can lead to production bottlenecks. The initial costs of equipment and infrastructure may be high, requiring both substantial investments in financial capital and technical expertise. The more you scale up production, the more pertinent questions of waste disposal, energy consumption, and material usage become.

Finally, scaling up microfluidic product development for mass production requires establishing new supply chains or strengthening old chains for acquiring necessary materials, chemicals, and components, providing its own logistics challenges.

2. Developing a User-Friendly Interface

When you develop commercial microfluidic devices, regardless of your market niche—from research and environmental assay to point-of-care testing—you must keep in mind that your target market is likely to know less than you about how to use microfluidic devices. An overly complicated product is difficult to sell.

To succeed in the microfluidics market, your device needs careful and considerate optimization for user-friendliness—its ability to be used by technicians or clinicians in the field with little difficulty. Your product needs to take into account the need for intuitive interfaces and simple step-by-step instructions for chip setup, fluid loading, and operation to ensure your customers can get the most out of your devices with the least training and preparation.

3. Adhering to Regulatory Compliance

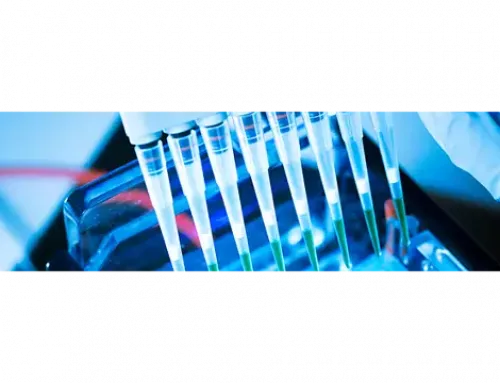

Particularly when building commercial microfluidic devices for medical diagnostic applications, ensuring compliance with the stringent regulatory frameworks your products fall under can be a significant challenge in LOC product design.

Obtaining necessary certifications and approvals can be time-consuming and expensive, requiring rigorous testing, validation, and documentation to demonstrate the safety, performance, and reliability of your product, adding to the numerous challenges in both designing and scaling up your microfluidic systems.

4. Building Market Awareness

The problem with designing an innovative product in any market, but especially the microfluidic device market, is ensuring that the people who need your product the most know that it exists at all. Microfluidics is a highly specialized field, and communicating to potential customers the capabilities and potential applications of your device demands effective marketing and educational outreach efforts.

Marketing microfluidic products can be an uphill battle, from making the applications of complex technologies simple to understand to convincing a typically conservative customer base to try a new product to generating the clinical data necessary to prove your product’s effectiveness over competitors.

5. Navigating Intellectual Property

The complexity of microfluidic technology makes navigating the patent landscape to safeguard your innovations and prevent infringement of your intellectual property and others particularly challenging. With rapid technological advancements in the field leading to increasingly complex designs that combine a wide range of disciplines from engineering and physics to chemistry and biology, establishing novelty and non-obviousness while avoiding infringement where technologies and disciplines converge is particularly difficult.

The global microfluidics market also compounds the difficulties of protecting intellectual property, requiring a global patent portfolio that takes into account the differing patent laws and regulations across different parts of the world.

Surmounting Commercialization Challenges in Microfluidic Product Development with Vantiva Precision BioDevices

From production to regulatory compliance to marketing to the legal landscape, the path from design idea to commercialized microfluidic product is a challenging one, but it isn’t one you have to walk alone. With Vantiva Precision BioDevices as your strategic manufacturing and design partner, you gain access to cross-disciplinary production and logistics expertise, cost-effective fabrication facilities, and an intimate understanding of the market to aid in the challenge of developing commercial microfluidic devices.

Find cost-effective solutions to scale up your production from rapid prototypes to high-volume manufacturing and anything in between

Optimize your designs for manufacturability, assembly, and user-friendliness with cutting-edge methodologies and forward-thinking design expertise

Take advantage of vast knowledge of the supply chain and unique logistics concerns across the microfluidics market

Reduce the risks of commercialization with attentive expertise and price leadership at every step in the way

If you have an idea for a microfluidic device that’s poised to shake up the market, meet with our engineers for help overcoming the challenges of microfluidic device commercialization.