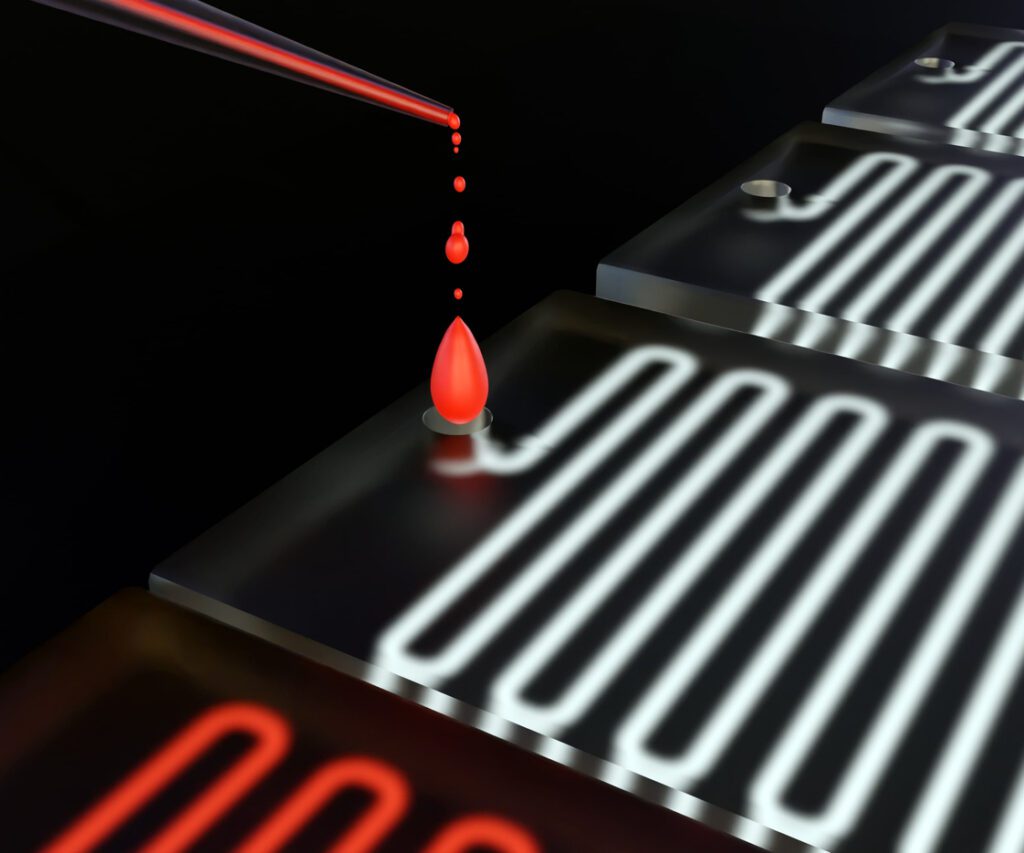

In the hands of everything from healthcare workers at point-of-care sites to researchers in life sciences laboratories to environmental field researchers, lab-on-a-chip devices powered by microfluidics have transformed day-to-day work with portable, efficient, high-throughput, and reliable assay solutions. As it stands, the microfluidic chips market is still primed for growth both inside and outside the medical industry.

In the hands of everything from healthcare workers at point-of-care sites to researchers in life sciences laboratories to environmental field researchers, lab-on-a-chip devices powered by microfluidics have transformed day-to-day work with portable, efficient, high-throughput, and reliable assay solutions. As it stands, the microfluidic chips market is still primed for growth both inside and outside the medical industry.

In order to take full advantage of future opportunities in the market, players in the market will need to continue innovating, exploring new microfluidics applications, new materials, and new fabrication techniques to build more efficient, more capable, and more diverse examples of microfluidic technology.

In this article, let’s explore a few of the future trends we’re expecting to see in the microfluidic chips market during this boom period.

Future Trends in Microfluidics Fabrication: High-Volume Manufacturing

To reach the markets with the fastest-growing demand for innovative lab-on-a-chip products, players in the microfluidics market will need to be prepared to scale up production to match. In any market, sudden spikes in demand for sought-after products or prototypes that pick up positive media attention can quickly overwhelm producers by forcing them to suddenly scale up from low-volume to high-volume production. Knowing how to produce your products faster and at higher volumes without sacrificing quality can prepare you for these types of situations.

The most cost-effective way to achieve higher manufacturing volumes while maintaining the quality your products are known for is to leverage the capabilities of contract manufacturers to scale up fabrication for you. Contract manufacturers in the microfluidics space can use high-volume manufacturing techniques such as roll-to-roll processing and scalable lithography to significantly scale up the production of prototypes and limited-run products without scaling up production costs to mass, enabling faster commercialization while maintaining consistent quality and reliability.

Future Trends in Microfluidics Applications: 3D Cell Culture Systems and Organs-On-a-Chip

The life science and pharmaceutical industries are some of the biggest drivers of microfluidics market growth today and in the foreseeable future, and one of the biggest demands in these industries are for microfluidic chips that go beyond simple fluid manipulation to include more sophisticated biological systems.

Advances in 3D cell cultures are allowing researchers to model tissue environments much more realistically than traditional 2D cultures. As more sophisticated and intricate microfluidics systems become the norm thanks to innovations in fabrication materials and methods, lab-on-a-chip platforms are making greater strides in replicating organ functions in controlled environments and improving studies of cellular behavior, disease mechanisms, and drug responses.

Future Trends in Microfluidics Fabrication: Precision Injection Molding

As injection molding technologies evolve in the medical industry, it is becoming an increasingly indispensable tool for the commercial production of microfluidic devices. Injection molding has become precise enough to fabricate highly complex micro-scale geometries, maintaining consistent quality from batch to batch—and this capability has made it a new cost-effective alternative to fabricating lab-on-a-chip devices compared to traditional methods such as photolithography.

Precision injection molding supports high-throughput mass production for durable, complex, and multi-layered microfluidic devices—and provides ample opportunities to implement the latest and greatest in advanced polymers into lab-on-a-chip devices for improved performance and better assay results.

Future Trends in Microfluidics Applications: Personalized Medicine

Drug delivery systems are a significant benefactor of growth and innovation in the microfluidics market. In one of our recent articles, we discussed some examples of microfluidics in personalized medicine in depth—such as using innovative new microfluidic consumables and biosensors to maximize the efficiency of cancer radiotherapy methods such as Boron Neutron Capture Therapy.

As microfluidic chips become easier and more cost-effective to fabricate, point-of-care medical professionals will have easier access to lab-on-a-chip and drug delivery systems that use microfluidics to move away from broken one-size-fits-all treatments and toward therapies that treat patients as unique individuals with unique health needs and considerations. We’re expecting to see some significant growth in personalized medicine as fabrication and design trends continue pushing the boundaries of innovation in the microfluidics market.

Future Trends in Microfluidics Design: AI Integration

“Artificial Intelligence” seems to be the hottest trend in any tech-adjacent market these days, and the microfluidics market is no exception. Don’t think that means future point-of-care testing devices will start talking back to you in that just-a-little-too-chipper ChatGPT tone or become potential vectors for SkyNet. Rather, we’re talking about advances in machine learning and large dataset processing techniques helping future lab-on-a-chip devices provide better, more actionable data.

As microfluidic designs become more sophisticated and capable of higher-throughput assay, the amount of data they can collect all at once grows in proportion. Modern artificial intelligence and machine learning have been built to sift through massive amounts of data faster than any human can and pick out trends in the data or other items of interest that could otherwise be missed. AI won’t be integrated into the microfluidic chips themselves, of course, but you can expect it to do a lot more heavy lifting with the data that portable point-of-care and research tools collect through their microfluidic chips.

Future Trends in Microfluidics Fabrication: New Bonding Techniques

Breakthroughs in new ways to securely bond layers of microfluidic chips are going to push lab-on-a-chip technology further and further by providing more secure and reliable bonding (no risk of leakage or malfunction affecting assay results) without impacting the functions of advanced integrated microfluidic features.

Our go-to example of recent game-changers in this field is Transparent Plastic Laser Welding, which ensures a stable, optically transparent bond between clear polymers ideal for microfluidics that rely on lenses and other micro-scale optics for their diagnostic and analysis functions.

Take the Reins of Microfluidic Chip Technology with Contract Manufacturing

There are still plenty of opportunities to be seized in the microfluidics market, and if you want to seize them, you’ll need a cost-effective, minimal-risk way to capitalize on current and future trends in lab-on-a-chip technologies. Rather than build your own in-house design, manufacturing, and distribution capabilities and shoulder the costs and risks yourself, a strategic partnership with contract manufacturers shoulders a significant share of the burdens of bringing new microfluidics to market. Talk to our engineers today and discover what you can accomplish with a partnership with Vantiva Precision BioDevices: Contact Us